- S231 - built-in temperature and humidity sensors.

- S214 - 4 analog inputs and 4 digital inputs.

- S250 - 6 digital inputs, 2 digital outputs and 1 rs-485 input.

- S251 - 6 digital inputs and 1 rs-485 input.

Monday, September 11, 2023

Advantech WISE-4220-S231 IoT Wireless Module

Tuesday, June 20, 2023

DIY Arduino Uno Data Logger

Wednesday, September 28, 2022

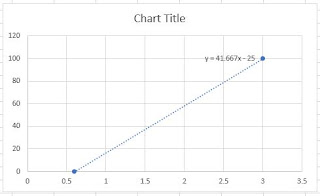

Homebrew SWR / Power Meter for HF and VHF

A friend is asking if I can fabricate a low-cost SWR/power meter with accurate performance up to 144MHz. One of the designs I have attempted is the modified Bruene directional coupler from Roy Lewallen, W7EL.

During the calibration process, I am using my Diamond SX200 meter as a reference standard, and my ICOM IC-2200H is employed to verify the power readings for both power meters. Additionally, I have prepared three distinct dummy loads – each with impedance values of 50 ohms, 75 ohms, and 100 ohms respectively. These dummy loads are necessary components for SWR calibration.

Assembling this project is relatively straightforward for me; however, the calibration process presents challenges. Notably, around 150MHz, there is a noticeable decline in power response. It appears that this might already be pushing the upper limits of my power meter's capabilities. Moreover, I've observed toroid transformer heating, particularly during continuous 60W testing.

I extend my heartfelt gratitude to my friend, Sir Leandro, for placing trust in and providing unwavering support for this undertaking. --- 73 de DU1VSS

Monday, September 26, 2022

Digital Tank Level Meter

At my current workplace, we operate with large tanks designed for storing huge quantities of chocolates. Regrettably, these tanks lack built-in sight glasses, imposing a burden on operators who must climb ladders frequently to gauge tank levels before initiating product transfers from the ball mill. One unfortunate incident occurred previously due to insufficient level awareness, resulting in chocolate overflow atop the tank. In response, we proposed a solution: constructing a dual-function digital level meter.

Firstly, the meter communicates with the PLC, notifying it when the tank reaches full capacity. This triggers an immediate signal to halt the transfer pump, averting potential overflows.

Secondly, a digital display unit was installed adjacent to the tank, facilitating quick and convenient monitoring of the chocolate product's current level within the tank.

Collaborating with a friend, we divided tasks: he managed sensor mounting fabrication, while I undertook sensor selection and the microcontroller's wiring and programming.

At the heart of this project lies an important hardware component – an IFM photoelectric distance sensor. Operating on the principle of laser light measurement, it generates a standard current output (4-20mA). The sensor boasts a maximum measurement range of 10 meters, aligning perfectly with our tank's height and volume parameters.

Sunday, June 23, 2019

Programming TK-3000:M6

Using my trusted "ugly construction technique", my programmer is now ready. Few more things needed in order to start programming and these are;

- KPG-137D software from Kenwood

- USB-Serial converter

Some settings in the KPG-137D needs to be set correctly such as the port number assigned in the usb-serial converter and the model / frequency range of the radio.

If you need a copy of the software just drop me a message below. ---73 de du1vss

Saturday, November 3, 2018

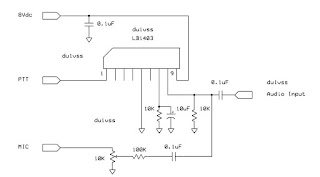

Voice Activated Repeater Controller Using LB1403N

The entire circuit is relatively simple and the only drawback is that it needs a high level of audio input coming from the receiver to keep the PTT close all the time during transmission. The protoype board is connected to my Icom IC-2200H as the transmitter and Icom IC-V80 as the receiver. ---73 de du1vss

Saturday, March 31, 2018

Mosfet Replacement in Pallet Amp Trick

I would like to share my trick in replacing the mosfet from pallet amplifier which I learned from my experiences in pallet fabrication and repairs. Most of us would like to unsolder those mosfet legs first one by one and is the most difficult to do since too much heating on those pcb pads would accidentally delaminate the copper from the board.

My shortcut in doing this is to cut the legs of the mosfet using a cutter blade but before doing this please make sure that the mosfet is verified defective!

After freeing the mosfet, now unsolder the remaining mosfet legs from the board using a soldering iron. Cleaned the board, apply fresh thermal paste and mount the new mosfet. 73 de du1vss